DonadonSDD LPD rupture discs

| Model | LPD |

| Materials | Stainless steel, Alloy 201, Alloy 400, Alloy 600, Alloy 625, Alloy C276, Titanium |

| Membrane | PTFE, PFA |

| Dimensions | DN 2"(50) – DN 20”(500) |

| Rupture pressure | 5 - 500 millibar g (depending on material and diameter) |

| Tolerance | from +/- 5 % to +/- 20% |

| Operating temperature | up to 265 °C |

| Operating margin | up to 60% |

| Vacuum support | Available |

| Fragmentation | No (membrane only) |

| Use under valve | Yes |

| Corrosion resistance | Good - can be protected with a PTFE membrane |

| Linings | Yes |

| Container | Mounted between flanges |

| Rupture sensor | Electrical, Magnetic, Inductive, Optical |

| ATEX EX II 2 GD Certification | Available |

DonadonSDD LPD model discs are a simple, reliable, accurate and economical solution for applications requiring extremely low pressure protection (positive or negative).

Their primary use is to protect processing and storage tanks, atmospheric vessels and silos with low design pressures, and therefore only able to withstand slight pressures and vacuums, against implosion or rupture.

A specially interesting application is in the protection of biogas digesters.

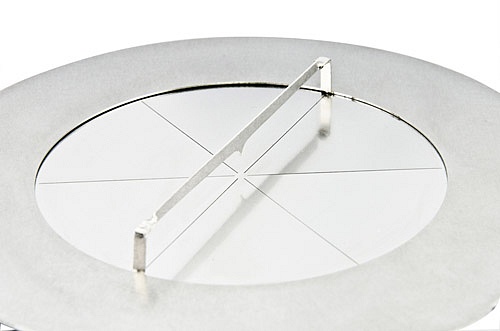

DonadonSDD LPD rupture discs are flat composite discs formed by four parts:

- a slotted, perforated metal part

- a seal membrane (usually in PTFE but also available in many other metallic or non-metallic materials)

- a protection section

- a calibration ring with blades to improve membrane rupture

DonadonSDD LPD discs open without fragmentation to prevent product contamination and can be customised to meet a broad range of non-standard specifications and applications.

LPD discs can be designed:

- for dual pressure and vacuum protection

- to resist vacuum or counter-pressure conditions

- complete with a burst detector